The TITK Group at the K 2025 trade fair in Düsseldorf

Organic adhesives, metal printing filaments, lightweight construction tapes: TITK Group showcases the full range of polymers at KHall 7, Booth B24 on Level 0 – this has been the traditional location of the TITK Group from Rudolstadt for many years when it comes to the world's most important industry gathering for the plastics industry in Düsseldorf. This year, the Thuringian Institute for Textile and Plastics Research e.V. and its two subsidiaries, OMPG and Smartpolymer, will once again be presenting innovative products and services related to research, testing, and transfer at the K trade fair. These include the multi-award-winning Caremelt® bio-hot melt adhesive, highly filled filaments for metal 3D printing, and carbon fiber-reinforced tapes for the most demanding lightweight construction applications.

We will present the following examples of our portfolio:

TITK - Thüringisches Institut für Textil- und Kunststoff-Forschung e.V.

- Caremelt® - fully bio-based and biodegradable hotmelt adhesive.

- Lightweight components made of natural fiber composites and with bio-matrix

- functionalized plastics, e.g. with an antiviral surface

OMPG - Ostthüringische Materialprüfgesellschaft für Textil und Kunststoffe mbH

- accredited testing services on plastics

- material testing of automotive applications, medical devices and consumer goods

- antimicrobial testing / biocompatibility testing

smartpolymer GmbH

- phase change materials (PCM) for thermal management, e.g. for effective temperature control of batteries

Effective temperature control of rechargeable batteries with PCM casings: TITK seeks project partners at K in Düsseldorf

Following preliminary tests on the temperature regulation of lithium-ion batteries, TITK has developed a passive thermal management system. Partners are now to be brought on board for further practical tests.

Lithium-ion batteries are mainly used as rechargeable energy storage devices in industry or in electromobility. They have a high energy density but are sensitive to thermal influences. Effective thermal management is therefore of great importance.

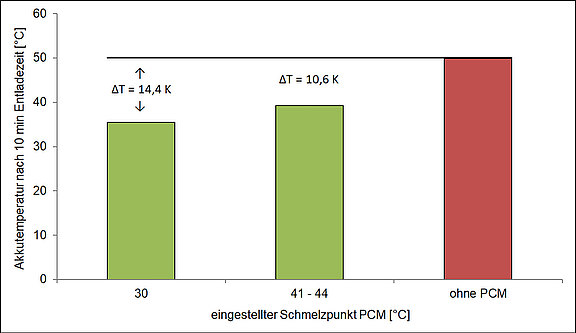

Active systems such as fans or fluid circuits are often used for this purpose. At TITK, however, the focus is on so-called phase-change materials (PCMs). For example, a shell for the passive cooling of lithium-ion batteries was produced and tested from a PCM compound developed in-house with a precisely adjusted melting temperature.

The result: "Due to the heat absorption of the PCM, the cell temperature could be significantly reduced during discharge," reports project manager Edgar Merting. This could reduce the cyclic aging of the batteries and significantly increase their service life. "The results of our experiments show that encapsulation with a PCM with a set melting temperature in the upper operating range of the cells can reduce temperature peaks during discharge and at the same time allow the batteries to be loaded for longer at high power levels," Merting said.

Based on these results, TITK is now looking for project partners for further, practical investigations on the topic. Interested parties are welcome to visit the TITK Group booth (Hall 7 / B24) at the K trade fair in Düsseldorf.

For effective surface hygiene: TITK develops plastic coating against viruses

Within the framework of two research projects, the TITK succeeded in binding and rendering harmless enveloped viruses, such as SARS-COV 2, with special polymer coatings on films and nonwoven materials.

A decisive factor in the epidemiology of a viral infection is the enormous resistance of many viruses to external environmental influences. They can survive on inanimate surfaces for days, weeks or even months without losing infectivity. For this reason, surface hygiene is an important aspect of infection prophylaxis. The TITK has also been dealing with this problem for some time.

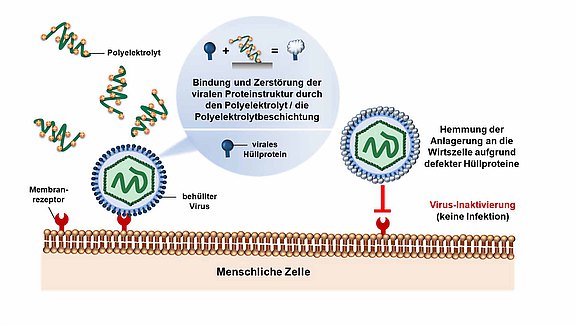

Scientists have now succeeded in applying virus-inactivating polymer coatings based on polyelectrolytic substances to plastic surfaces and reliably demonstrating their effectiveness. The effectiveness test was carried out in two ways: First, viral envelope proteins of the SARS-CoV were genetically engineered at the institute and the mechanism of action of the polyelectrolyte coatings was investigated on a molecular biological level with the help of these. In parallel, the TITK and its subsidiary OMPG - Ostthüringische Materialprüfgesellschaft für Textil- und Kunststoffe mbH - developed a test procedure based on the existing ISO 21702 and ISO 18184 standards to investigate the antiviral efficacy of various plastic surfaces and textiles using both an enveloped and an unenveloped bacteriophage.

It was found that the viruses are not only bound by the polyelectrolyte coatings on films and nonwoven materials, but their coat proteins are effectively destroyed. Consequently, the virus can no longer dock to the host cell and infection can no longer occur.

These and other TITK research results will be presented at the K trade fair in Düsseldorf, Germany, from October 19-26, 2022. At the TITK Group booth (Hall 7 B 24), visitors and customers will be able to talk with TITK scientists and with representatives of the laboratory management of the subsidiary OMPG - an accredited testing laboratory.