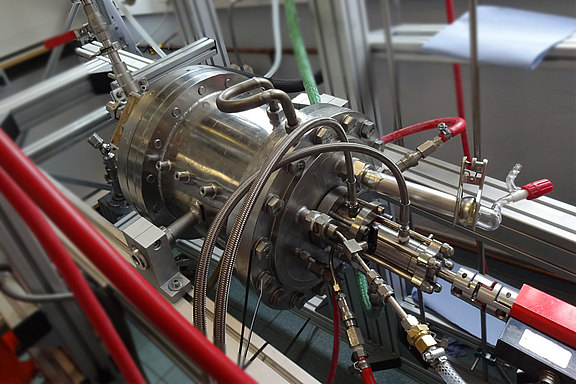

Pilot plant for polymerisation and polycondensation

The TITK produces polymers for functional materials in test facilities. Close cooperation with melt spinning, compounding and injection moulding techniques is important here. Polyester copolymers for flame retardant applications and for other functional fibres are developed at the TITK. For this purpose, various comonomers and nanoscale mineral additives can be incorporated into the polymers in situ. The particle size distribution of the additives is determined. In addition, polycarbonates can be produced via the transesterification of diphenyl carbonate with bisphenols on a 1 and 5 kg scale. In the course of the development of modified polyacrylates and polyacrylonitriles are polymerised at TITK via radical emulsion and suspension polymerisation. The synthesis of new comonomers and catalysts takes place in the synthesis laboratory. New raw materials can be tested in small polymerisation plants on a 50-100 g scale. Analyses are carried out during the process in the laboratories. In cooperation with industrial partners and a partner for special mechanical engineering, the plants can be modified according to customer specifications.

Technical equipment

- 10-l polyester autoclave for direct esterification of terephthalic acid and transesterification of dimethyl terephthalate

- Two-stage polyester plant with swivelling ring reactor system Kämpf

- 10-l polyamide autoclave for the production of PA6, PA66 and partially aromatic polyamides

- Two-stage polycarbonate plant according to the transesterification process and melt polycondensation up to 5 kg System EPC

- Solid phase polycondensation (SSP) for polyamides and polyesters in 1 kg scale

- Glass apparatus for polycarbonate synthesis by melt polycondensation in 1 kg scale

- Glass reactors 1-3 l for radical suspension and emulsion polymerisation

- Aluminium reactor 20 l for the production of acrylonitrile copolymers EPC system

Research focus

- New polyester-based flame retardant fibre bases

- Antimony-free catalysis for polyester synthesis

- New polyester materials based on renewable raw materials

- New polycarbonate materials using bio-based comonomers

- Recycling of polyester materials by depolymerisation and repolymerisation in the sense of circular economy

- Thermoplastic reinforcing fibres for thermoplastic composites

- Polyacrylonitrile copolymers for carbon fibre precursor fibres for the development of novel wet spinning processes

- Antibacterially active polymers and their incorporation into functional fibres