Every successful technical implementation of new developments is preceded by precise a targeted analytical characterization of process-relevant parameters, with regard to raw materials used and formable polymer solutions employed.

In addition to new developments, analytical support also assists in the optimization of existing processes and helps in the development and process adaptation of pulps for different forming processes.

Analytical methods

Cellulose analysis

- α-Cellulose content

- Content of carboxyl and carbonyl groups

- Alkali, alkaline earth and heavy metal ion content (AAS, ICP-OES)

- Ash content

Molecular weight and molecular weight distribution

- Intrinsic viscosity / average degree of polymerization (Cuen, Cuoxam, Schott AVS capillary viscosimeter)

- GPC /SEC

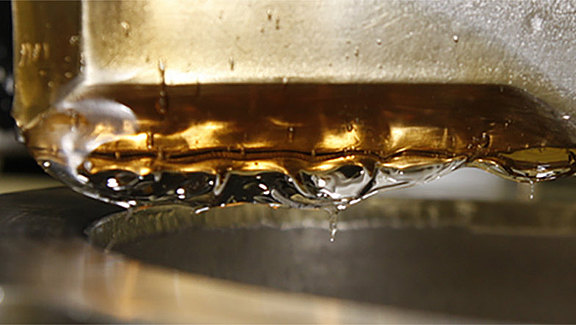

Solution characterization

- Polarizing microscope (Zeiss)

- Particle analysis (laser diffraction, Helos Particle Analyser)

- Rotational or oscillatory rheology (Haake Mars® rotational rheometer)

- Extensional rheometer (CaBER)

Structural analysis

- Degree of crystallinity (WAXS, Bruker)

- Pore size and distribution (mercury porosimetry, BET)

- REM / EDX

Thermal analysis

- Thermogravimetry

- DSC