In view of the increasing use of fiber-reinforced plastics in the automotive and aerospace industries, as well as in wind energy and mechanical engineering, the automation of component manufacturing processes plays a decisive role. The TITK's plant concept for the automated production of stack structures represents an interesting approach in this respect.

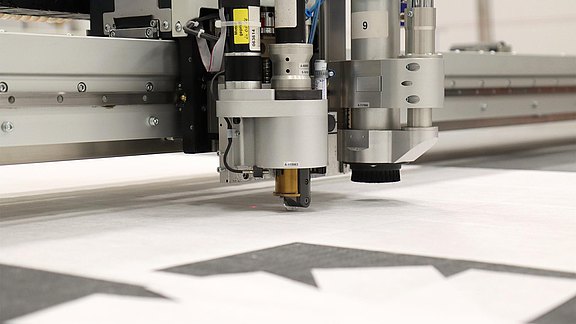

Here, the reinforcing material is placed on the cutter table in one or more layers. After cutting, the blanks can be automatically removed by a special handling system and temporarily stored in magazines. Stacking is automated according to the respective laminate structures. Depending on the requirements, the stacks can be sewn or spot-welded.

Advantages of automated stack production:

- high degree of automation

- consistent, reproducible quality

- short cycle times

- load-oriented fiber orientation

- cut-optimized, low-waste material use

- high flexibility with regard to material concept and component geometry

- low risk of rejects