Technology

TITK has developed piezo fibers that convert mechanical energy into electrical energy. The fibers are manufactured using a spinning process and can thus be integrated very flexibly into textiles or composite materials or applied to base bodies. This makes it possible to measure the changes in shape of the substrate or the base body in real time over a very broad band and to detect material changes such as aging of the substrate.

Properties

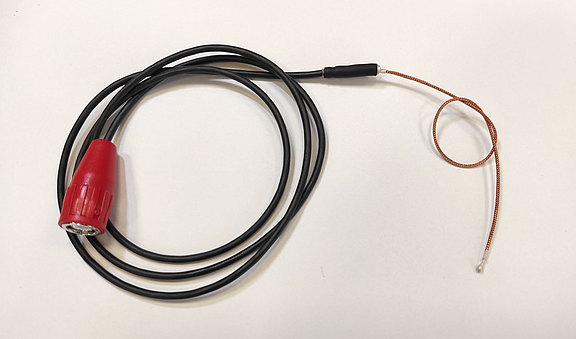

- melt spinning of a core-sheath fiber in a continuous process with PVDF as the functional material

- very broadband piezoelectric signal conversion (lower Hz to upper MHz range)

- free formability of the fiber, thus very good adaptation to the base body

- flexible length of the sensor fibers (cm to m range)

- diameter 0.8 ... 1.2 mm

- integration into different matrix materials (polymeric, mineral) possible

Fields of application

- Mechanical engineering: Detection of tool wear through structure-borne sound analysis (use of the piezo fiber as a linear, integral sensor also as a retrofit option for existing machines).

- Composite materials: Detection of material defects and material aging due to viscosity degradation or delamination of reinforcing fibers

- Construction industry: Measurement of structure-borne sound in walls and floors to determine the structural strength of building materials and the setting of mineral materials

- Smart Home: Location-resolved movement detection of the inhabitants of a house by using intelligent area sensors in floors or clothing (energy conversion of the movements of the persons into electrical voltages as well as signal interpretation)