Due to their low material consumption and the wide range of design possibilities, foams have become indispensable in the fields of construction, packaging, footwear and many lightweight construction applications. As an application-oriented research institute, TITK is available as a competent partner with regard to analysis, development and consulting for foams.

The core competences include the application-oriented development of foams with physical and chemical methods using various gases. Furthermore, investigations are carried out regarding fiber reinforcements according to maximum filling degree and optimal fiber length for bubble stability. Based on classical, petro-based, but also biobased and / or biodegradable thermoplastic polymers, innovative cell structures are researched and developed with different fillers to suit the application.

Development and modification of biofoams

- Based on biobased and/or biodegradable materials such as starch, PLA, PBS, PCL, PHA, PBAT and their blends, new materials can be adjusted to suit the process and different morphologies can be created.

- The know-how is based on TITK's many years of expertise in the field of these materials and their processing into new innovative materials.

Technical equipment

Analytics

- Material properties: Density, pH, hardness, etc.

- Rheometry (plate/plate, cone/plate rheometer): viscosity, loss factor, etc.

- Thermal analysis (DSC, TGA): transition temperatures, degree of crystallization, kinetics, filler content, etc.

- Thermomechanical analysis (DMA): glass transition temperature, viscoelastic material properties

- Mechanical testing (universal testing machine): tensile shear strength, peel test, bending properties, pressure test

- Weathering resistance (xenon test chamber): resistance at elevated temperature, humidity, solar radiation

- Chemical resistance: acids, bases, solvents, etc.

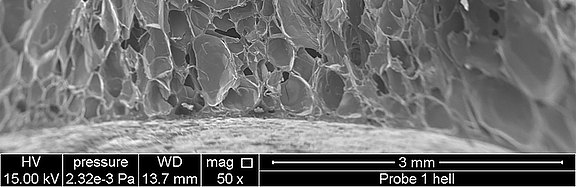

- Surface analyses (FTIR, AFM, SEM): material, structural

- Cell size distribution by light microscopic examination

Laboratory scale

- Twin screw extruder 40 L:D

Pilot plant scale

- Twin screw extruder 48 L:D

- Pressure-superimposed underwater pelletising (also for particle foam)

- Side feed for fillers

- Gravimetric metering for reproducible process control

- Pressures up to 160 bar, temperatures up to 350°C