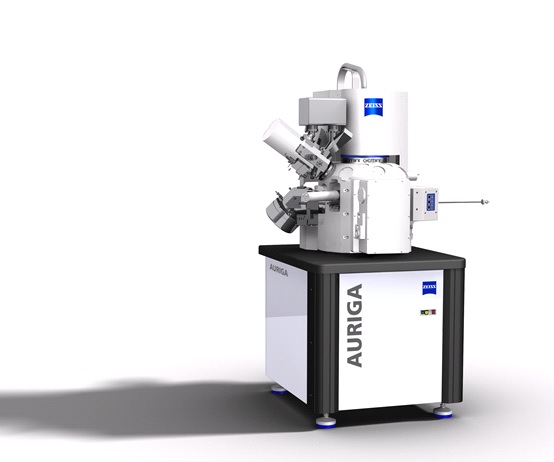

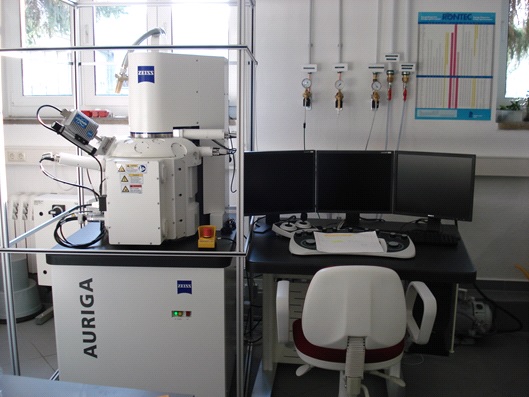

SEM: "AURIGA TM" - Crossbeam base system, Zeiss

High-resolution scanning electron microscope with Schottky field emission cathode

High-resolution scanning electron microscopy is suitable for a wide range of applications in the field of materials characterisation and, due to its high depth of focus, is preferred for imaging unevenly structured surfaces. In addition, it is used to characterise micro- and nanostructures for materials research and development as well as for quality assurance and damage analysis.

Application examples

- Morphological examination of cross-sections to elucidate layer structures

- Phase distribution in plastic blends

- Investigation of surface topography

- Fracture surfaces in plastic components

- Media attacks and their material wear phenomena

- Defective surface coatings, roughnesses

- Crazes, cracks, fibre-matrix adhesion, fibre distribution

- Pigment and filler distribution

- Analysis of material inhomogeneities (blowholes, inclusions)

- Structure measurement

- Detection and measurement of impurities

- Investigations by means of material contrast

- Spherulite structures and processing influence

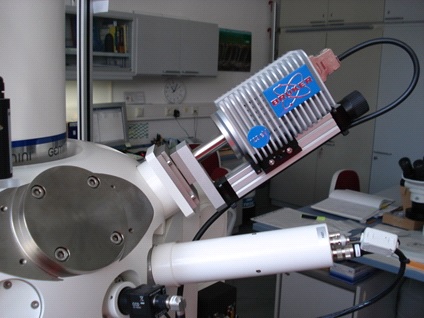

- EDX X-ray micro-range analysis for material identification