Task

One of the most important product properties of modern functional textiles is breathability. Breathable textile composites, membrane systems (e.g. in outdoor jackets) simultaneously provide weather protection and climate compensation due to their special molecular structure and hydrophilic character. High demands are therefore placed on the surface composite of textile base fabric and membrane: For example, the adhesive must not negatively influence the functional properties of the membrane, or only to a small extent. Nowadays, however, the breathability of the membrane is many times higher than that of the adhesive. A restriction due to the applied adhesive is therefore unavoidable. In order to keep the reduction in function as low as possible, improving the breathability of the adhesive is the focus of the R&D activity. The aim of the project was to improve the breathability of preferably reactive textile hotmelt adhesives with suitable additives.

Results

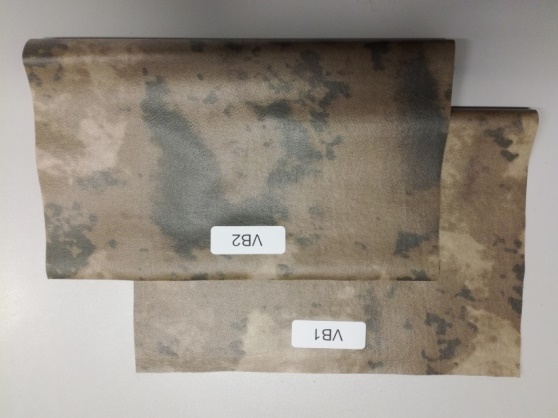

Two approaches were investigated. Firstly, micropores were incorporated into the adhesive to improve water transport from the inside to the outside. The second approach dealt with the diffusion of water molecules through the adhesive. This was investigated with the use of plasticisers and specifically selected additives with a high water vapour permeability. By incorporating a microporosity, the breathability could be partially improved. Modification with plasticisers and additives also led to an increase in water vapour permeability. As expected, however, the adhesive properties of the untreated reference adhesive could not be achieved. However, especially with the use of plasticisers, the breathability was significantly increased with sufficiently good adhesive properties. The practical test on a laminated material also confirmed the results on the adhesive. The breathability of the entire laminate could be improved by up to 12% by adding 5% dibutyl sebacate. It is expected that the addition of >5% plasticiser will also further improve the breathability of the composite.