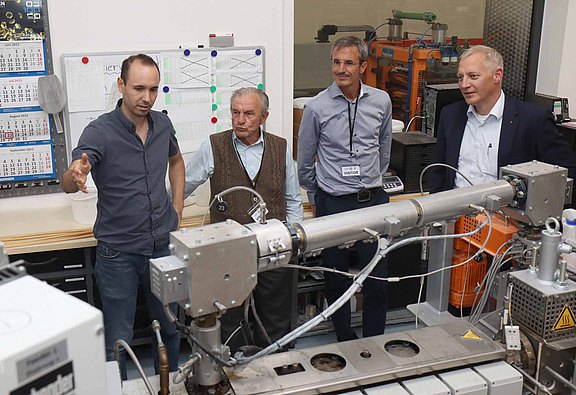

Peter and Jochen Pelz visit the "birthplace" of Caremelt® and have a lively discussion about the broad portfolio of the research institute.

At the invitation of Director Benjamin Redlingshöfer, Peter and Jochen Pelz from the Ernst Pelz Foundation in Geretsried (Bavaria) now paid a visit to TITK. Starting point for the flying visit: The biobased and biodegradable hotmelt Caremelt developed at the Rudolstadt research institute had been awarded the prestigious "Ernst-Pelz-Prize" in Würzburg at the beginning of July.

Established in 1992 on the initiative of Peter Pelz, the award aims to further advance technologies for the utilization of renewable raw materials and also to promote them financially. In recognition of the entrepreneurial achievements of his father Ernst Pelz (Empe Werke), Peter Pelz named the award after him and four years later established the charitable foundation of the same name. Its activities are particularly valuable because it does not distribute its funds according to the watering can principle, but has set itself the task of "identifying and supporting germ cells that decisively advance our human development (...)". The focus is therefore on promoting research and development in the field of renewable, regenerative raw materials and alternative energies. At the same time, however, the foundation also supports young people entering entrepreneurial activities as well as school and vocational training projects and cultural and local heritage preservation.

A few days ago, Peter Pelz and his son Jochen accepted the offer from Rudolstadt and personally saw for themselves the conditions under which the hotmelt adhesive, which has already won several awards, can be produced here. What exactly does it consist of? What does it have to be able to do? How can it be industrially produced and processed? And for which applications is it suitable? - The curiosity of the guests was huge.

Together with the responsible project manager Andreas Krypczyk, Benjamin Redlingshöfer also took them to the extrusion pilot plant, where a batch of Caremelt was produced as granules. Meanwhile, Andreas Krypczyk was able to report on a new research project on edgebands for the furniture industry. The company is working closely with an adhesive manufacturer and a resin producer on this project. As Benjamin Redlingshöfer emphasized, this strict application orientation is essential for business-oriented research without basic funding.

Incidentally, the five colleagues involved in the Caremelt project also have reason to be pleased about the Ernst Pelz Prize. Half of the prize money of EUR 10,000 will go to them as a special payment. The other EUR 5,000 will be used for further research projects in the working group.