Hall 7, Booth B24 on Level 0 – this has been the traditional location of the TITK Group from Rudolstadt for many years when it comes to the world's most important trade fair for the plastics industry in Düsseldorf. This year, the Thuringian Institute for Textile and Plastics Research e.V. and its two subsidiaries, OMPG and Smartpolymer, will once again be presenting innovative products and services at the K trade fair. These include the multi-award-winning Caremelt® bio-hot melt adhesive, highly filled filaments for metal 3D printing, and carbon fiber-reinforced tapes for the most demanding lightweight construction applications.

Düsseldorf/Rudolstadt – Unidirectionally reinforced tapes are key materials for efficient and sustainable lightweight construction. They enable components to be manufactured in a targeted, resource-saving, and performance-optimized manner by placing fibers exactly where they are needed for mechanical stress. This provides tailor-made semi-finished products for lightweight construction. At the K trade fair, TITK will present the results of a research project on this topic. Specifically: new, dry narrow-band fabrics based on 50K carbon fiber rovings. These tapes were produced with customized sewing threads and improved thermofixation and processed in an automated, robot-assisted tape laying process.

Other exhibits by the TITK Group document the industry's growing interest in the multi-award-winning Caremelt® bio-hot melt adhesive. It has recently been adopted for production by, for example, the industry leader in animal burials, ROSENGARTEN from Bad Bergen, and Kneisz Design from Weimar. Caremelt® has also been on display at Expo 2025 in Osaka, Japan, since April and will remain there until mid-October.

As the first completely bio-based and biodegradable hot melt adhesive, it requires no fossil resources whatsoever and offers the possibility of making products that are already manufactured sustainably completely environmentally friendly. Recycling is virtually impossible, especially with adhesives. This makes it all the more important that no microplastics are produced at the end of the product life cycle. The potential areas of application for Caremelt® are very diverse. They range from the packaging, hygiene, and textile industries to the automotive sector and the shoe, wood, and furniture industries. The adhesive is CO2-neutral, and globally available raw materials make its industrial production cost-effective.

Polymer-based radiation elements for dielectric resonator antennas are aimed at a completely different area of application. These highly specific components are used in antennas for local broadband systems in industry, forestry, and agriculture, for security services, and for WLAN hotspots in building radio systems and in means of transport. TITK has been researching these polymer semi-finished products for some time and has succeeded in making them more attractive than conventional products with high permittivity and low attenuation loss.

The aim of the research was to develop dielectric-filled polymer substrates and semi-finished products that can be used as radiation elements, initially in hotspot antennas between 2 and 3.7 GHz and 5 and 6 GHz, but also at higher frequencies in the 5G range. For this purpose, polymer composites with ceramic components such as titanates with a high filling degree and permittivity were processed into radiation elements using both classic plastic processing methods such as extrusion, injection molding, and compression molding, as well as additive manufacturing technology such as the FFF (fused filament fabrication) process. The dielectric polymer composites used can be thermoplastically processed even at very high fill levels, enabling a wider range of permittivity to be covered compared to commercial laminate composites.

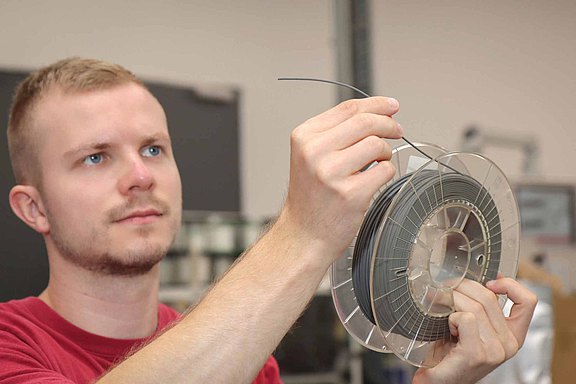

To investigate how metal 3D printing processes can be made sustainable and recyclable, TITK has collaborated with ifw – Günther Köhler Institute for Joining Technology and Materials Testing (Jena) and GFE – Society for Manufacturing Technology and Development (Schmalkalden). The project “Circularity-optimized process chain for the additive manufacturing of metallic tool components via material extrusion” has now been completed since June, allowing concrete results to be presented in Düsseldorf.

TITK produced filaments for FFF printing from specially developed blends with a filling degree of up to 90 percent metal powder by weight. After printing the filaments, the plastic is first removed using solvents and then thermally. After subsequent sintering, a dense, purely metallic component is obtained.

Conventionally available filaments require toxic or flammable solvents for debinding. In contrast, the continuous filaments developed at TITK allow water or water-based solvents to be used before the furnace process. With the recovery of the dissolved binder and a functionally integrated lightweight design, the components also contribute to resource conservation. In a follow-up project, further binder systems with other types of steel and ceramic fillers are now to be investigated.

TITK Group at K from October 8 to 15 in Düsseldorf – Hall 7, Level 0, Booth B24.