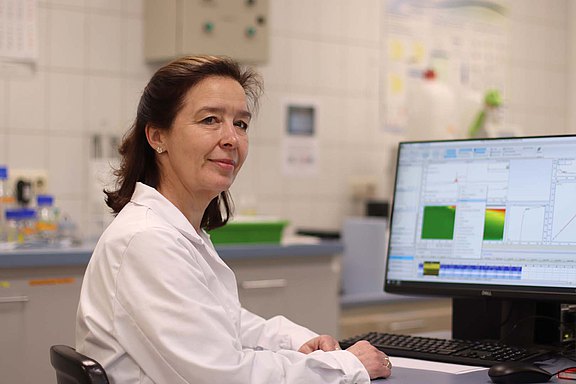

It was clear to Anke Krämer at an early stage which direction her career would take. Chemistry lessons in the 8th grade held such a fascination for her that she still blames her teacher for her career. Getting to the bottom of unknown substances - that was already the greatest thing for her back then. Today, that is exactly her profession: as head of chemical analytics in the TITK Group. "We test products that are essentially to be marketed in the consumer products sector. Not only finished consumer goods, but also their starting materials," Anke Krämer summarises.

The path to this point was initially quite straightforward: A-levels in 1989 at home in Riesa, Saxony, then the search for a suitable university to study chemistry, finally enrolment at the traditional Friedrich Schiller University in Jena. "The end of my studies in 1994 coincided with a somewhat difficult time for young people looking for a job," Anke Krämer thinks back. But her diploma father found her a job in a newly founded company in Jena. There she could devote herself fully to research on her favourite topic - chromatography. In this special analytical method, mixtures of substances are broken down into their individual components so that they can be determined separately.

So Anke Krämer "stuck" in Thuringia, met her husband, started a family, had two children. Until, after 14 years, the time seemed right for a new professional start. She was already familiar with the TITK Rudolstadt from research projects and her family environment. Now there was offered a position as "group leader for organic analytics". "That's a good fit, they're looking for you!" Anke Krämer immediately said.

From the big city to the small town to get ahead professionally

She threw her hat into the ring and decided to move on professionally. With everything that was necessary: a move to Rudolstadt, 40 kilometres to the southwest, new colleagues, more responsibility. But unfortunately, it also put an end to what was then her great passion. Almost 30 years she had remained faithful to dance in her spare time, twelve of them as the leader of a youth formation in Jena. And she did this with all her heart and soul - as trainer, choreographer, costume dressmaker and manager of all performances in one person.

Today, another 13 years later, Anke Krämer looks back with satisfaction. At the TITK, she has long since risen from group leader to laboratory and division manager, introduced new quality assurance measures and knows she has a wonderfully functioning team at her side. She has staff responsibility for 17 colleagues and works with a good 150 regular customers. Her daily work is determined by service assignments in analytics. The connection to industry-related research is inevitable: "Because we are always in contact with business partners who want to develop new products from new materials. This often requires completely different or at least modified manufacturing processes. Including customer-specific analytics.

"Our expertise in material testing is also becoming increasingly important in the development of new plastics," says Krämer. Whereas in the past the main focus was on the physical-mechanical properties of materials, such as processing, resistance or light fastness, now the chemical composition is increasingly coming into focus. "The more complex the manufacturing processes become, the more intensively you have to monitor chemically how the plastic is created. This is the only way to ensure that the end product meets exactly the desired requirements."

Analytical processes co-designed for one of the world's largest polycarbonate plants

As part of a research project, TITK supported EPC Engineering & Technologies GmbH from Rudolstadt in 2012 in implementing a polymerisation process for polycarbonate production. The engineering service provider and industrial plant manufacturer is now applying these findings worldwide in technology transfer. For example in China, where the first large production line was built in the coastal province of Zhejiang from 2013 to 2015. A second plant followed in the same region at the beginning of 2021. Embedded in a mighty petrochemical complex with a total area of 40 square kilometres, it is considered one of the largest polycarbonate plants in the world. Capacity: 260 tonnes per day. For one of three planned lines, mind you.

Polycarbonate is a translucent plastic that can be encountered frequently in everyday life. "The most prominent example is optical storage media such as CDs and DVDs," says Anke Krämer. But it is also used in LED lights and as an alternative to glass - for example in glasses, headlights or visors. In the automotive sector, polycarbonate is mostly used as a compound, i.e. mixed with other materials. "It is an extremely exciting polymer," Anke Krämer enthuses about its physical and chemical properties. "The high impact strength, good heat resistance, its transparency and comparatively simple thermoplastic processing open up numerous application possibilities for polycarbonate." And thus a huge market. New production sites in China are being designed very big accordingly.

Research focuses on practical application and economic relevance

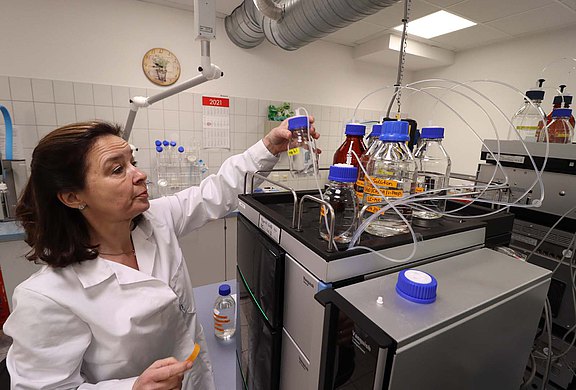

How does the polymer grow? What side reactions can occur? How can the process flow be controlled at all times? - Such questions are asked by those who help design the process steps for such mega- plants. This is precisely why Anke Krämer has now visited the Middle Kingdom for the second time. On behalf of the Thuringian engineering company, she helped develop the analytical procedures required for plant control and helped implement them on site. Including training of the Chinese laboratory staff.

While the first production plant required several short stays between 2013 and 2015, this did not work for the second plant. In times of a pandemic, when travellers to China must first spend three weeks in quarantine, this is simply impractical. So this year Anke Krämer flew to the East China Sea for ten weeks at a time. You can imagine how big the stress test was for her family. But she sees that as the price to be paid for putting one's heart and soul into completing a gripping task in the best possible way or for cracking a problem that is classified as unsolvable. After all, these projects also led her to tackle her doctorate at the age of almost 50. For now the perfect topic had suddenly presented itself: "Development of chromatographic methods for the characterisation and control of technical polycarbonate processes".

Chromatography, especially high performance liquid chromatography (HPLC), is very important for polycarbonate production in particular, says Krämer. "Because you can hardly determine the starting materials and the by-products any other way." How these analytical processes can be made faster, more effective and better - that's what she wants to answer in her dissertation. The most recent assignment in China set her back quite a bit. At least that's what she thought at first, when the new travel date was set. But the opposite happened: The experiences in industrial plant construction in the Far East helped her to sharpen her view once again. Today she knows: Scientific aspirations and industrial needs must also be brought together in her doctoral thesis. "In the end," says Krämer, "the most important thing is that new findings from research can be translated into practical applications.

Author: Steffen Beikirch, TITK

This portrait was first published by the German Industrial Research Association Konrad Zuse.