TITK is establishing a new innovation centre for the textile circular economy. Under the name ‘DICE – Demonstration and Innovation Centre for Textile Circular Economy’, a state-of-the-art technical centre and laboratory building was officially inaugurated on 12 December 2025 on the institute's own premises in Rudolstadt.

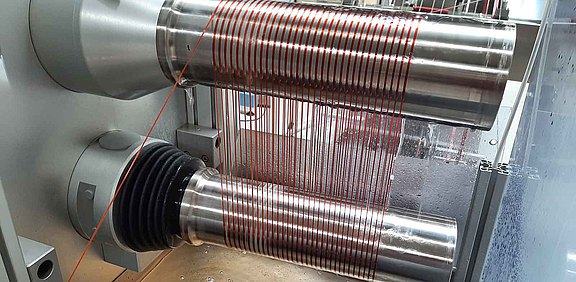

DICE will set new standards for industrially scalable closed-loop recycling processes (fibre-to-fibre recycling) for cellulose and polyester fibres – a real boon for the textile value chain. DICE's mission is to research and test solutions for practical and holistic textile recycling.

The focus is on developing new, industrially scalable circular processes, especially for cellulose and polyester fibres. In this way, TITK aims to make an important contribution to the transformation of the textile value chain.

The timing is highly relevant: European legislation requires the mandatory collection and recycling of used textiles starting this year.

At the same time, the textile circular economy is growing rapidly worldwide.

The recycling of mixed textiles in particular is a key challenge that DICE will address intensively.

The new innovation centre has a modern, four-storey laboratory and office building at its disposal, as well as a technical centre and test hall with a floor space of around 1,000 square metres. The new building will house a biology laboratory and a pulp laboratory, among other facilities. The test hall will focus on two main areas: polyester recycling and cotton recycling. In addition, research and testing of alternative pulp suppliers is also a key area of work at DICE.

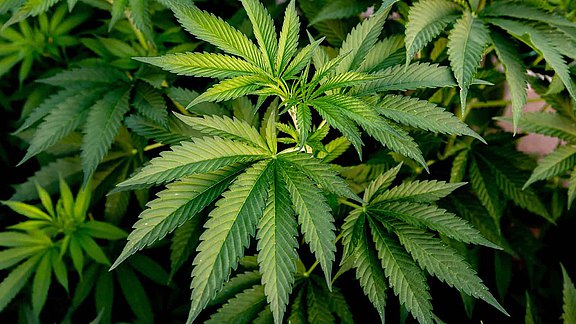

For more than 30 years, TITK has been dedicated to sustainable cellulose-based textile fibres. These Lyocell fibres have now undergone significant further development: they no longer use pulp from wood, but from fast-growing hemp, for example.

With a total investment of around €11.5 million, including technical equipment, DICE is TITK's largest single project to date. The Free State of Thuringia is supporting the construction with a total of €8 million in GRW and FTI funding.

Sixty-three partners – including well-known companies such as Adidas, Vaude, Continental and Head – have already committed to working with DICE. Numerous research institutions, associations and networks are also supporting the flagship project in Rudolstadt, Thuringia.

At TITK itself, more than 20 research projects related to the textile circular economy have been completed in the last eight years alone.

Eight projects are currently in progress, with a further 14 projects in the application stage.

Current research projects

Can cellulose from hemp be recycled into textile fibres multiple times? The answer can be found in our 300% recycling project: hemp pulp is used to produce Lyohemp® fibre using the Lyocell spinning process and is recycled three times without the addition of new raw materials. This recycled material was used to produce a polo shirt with excellent textile properties.

Project manager:

Dr. Marcus Krieg

Industrial hemp has excellent textile properties, a very small carbon footprint and unique ingredients. Non-psychoactive cannabidiol (CBD) has many positive pharmacological effects, including anti-inflammatory and antioxidant properties.

A cellulose-based cosmetic textile with a high CBD content is unique to date.

Project manager:

Dr. Frank Wendler

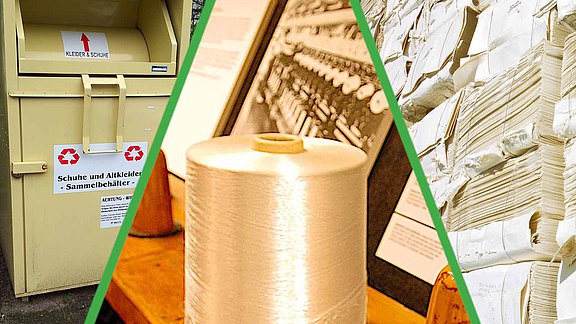

Every year, 92 million tonnes of textile waste are generated worldwide, half of which comes from polyester-cotton blend textiles. In order to use this as a source of raw materials, cyclical chemical processes for producing new polyester and cellulose fibres need to be developed. This will enable closed material cycles to be established in a circular economy.

Project manager:

Dr. Peter Bauer

Sheep's wool is a valuable raw material and also very attractive for sustainable textile developments. The aim is to test sheep's wool residues and wool products from textile recycling for their suitability by means of solution forming and to highlight the advantages of the functional properties of these innovative fibre products. Partner: NH DyeAGNOSTICS GmbH.

Project manager:

Dr. Katrin Römhild

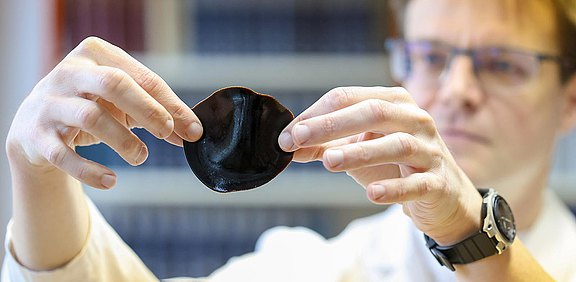

The aim of the project is to develop a hydrogel based on lignin and chitosan. This is to be used as a medical wound dressing, whereby the antibacterial properties of these natural substances can be put to good use. The hydrogel to be developed thus consists of renewable raw materials and is 100% biodegradable.

Project manager:

Dr. Stefan Fischer

Until now, the Lyocell process for producing artificial cellulose fibres has required specially prepared pulp. The process can be adapted to use raw materials that were previously considered unsuitable. Pulp from recycled textiles offers ecological added value and appeals to customers, while paper pulp can reduce the production costs of the fibre.

Project manager:

Menno Foorden

Cellulose pulp from recycled cotton textiles will soon be used in the production of artificial cellulose fibres. In order to use these fibres in the Lyocell spinning process, the degree of polymerisation must be adjusted and the accessibility of the pulp improved. Enzyme treatment is an effective measure for this purpose.

Project manager:

Christoph Kindler

The project is developing sulphur-free pulping processes for extracting cellulose from agricultural raw materials and recycled textiles. These cellulosic materials are analysed and optimised for the Lyocell process in order to spin them into high-quality textile fibres.

The research is being conducted in collaboration with IPHC Tharandt.

Project manager:

Heinrich Menning

The aim of the project was to develop and use an innovative recycled yarn made from Lyohemp®, which is processed within a modular collection. The practical overall process was designed to ensure that the recycled yarn can be continuously recycled in a closed loop in order to conserve resources.

Project manager:

Michael Sturm